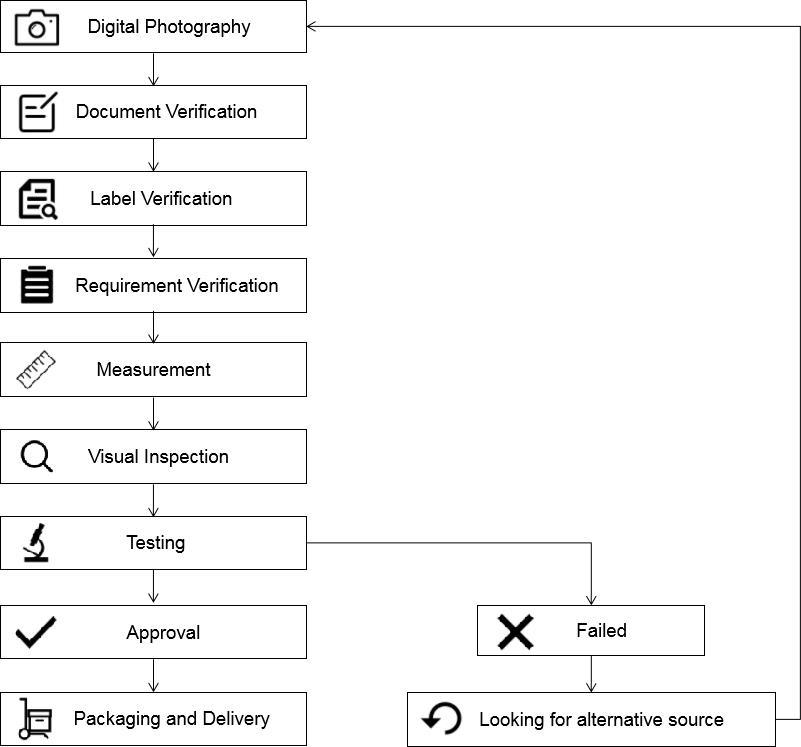

To ensure that every customer can receive satisfactory products, we established a strict quality assurance system as follows:

Each product must go through strict testing. The detailed items includes:

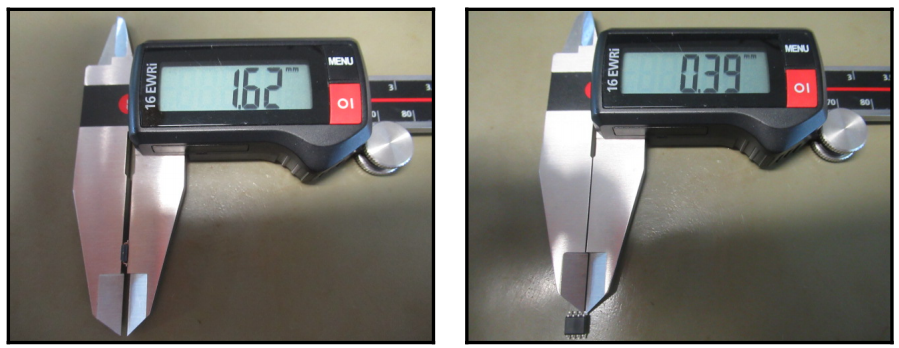

*Measurement--To check whether the devices have the same exterior configuration as shown on the Package Outline Drawing (POD).

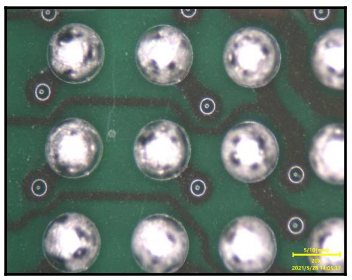

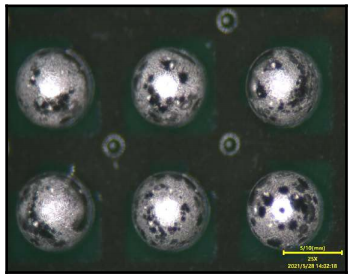

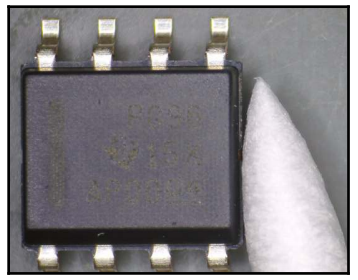

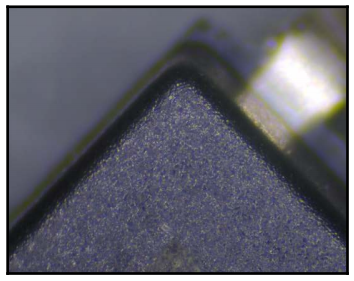

*100x Microscope Inspection----To assist with the visual inspection(surface printing, main part and pins of each chip, consistency of the same batch of chips) and help discern whether a chip is authentic or fake.

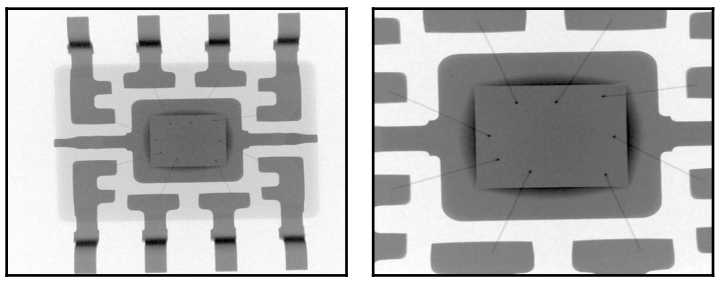

*X-ray Test--To check whether there is a physical defect of the grain, lead frame and gold wire.

*Permanency Test--To check whether the mark on the surface of the chip is original or re-type writing.

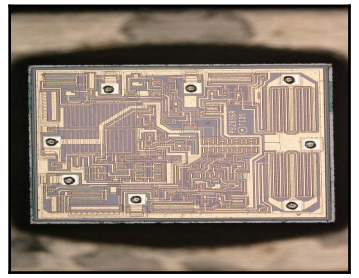

*Decap Test--To check the important marks, layout and defective workmanship of the grain surface.

*Programming Test--To check whether there is any data in the programming device.

High magnification, multi-angle inspection, and a large-area inspection platform. Defect inspection in IC encapsulation, e.g.: layer separation, cracking, void, and line integrity. It can penetrate inside the package & check inside quality.

High-performance lighting enables minute surface details to be observed and analyzed. Motorized lens turret enables seamless transition in magnification from 20 - 6000x.